Product description

Used Coil Line System – Complete HVAC Sheet Metal Fabrication Line

Key Features:

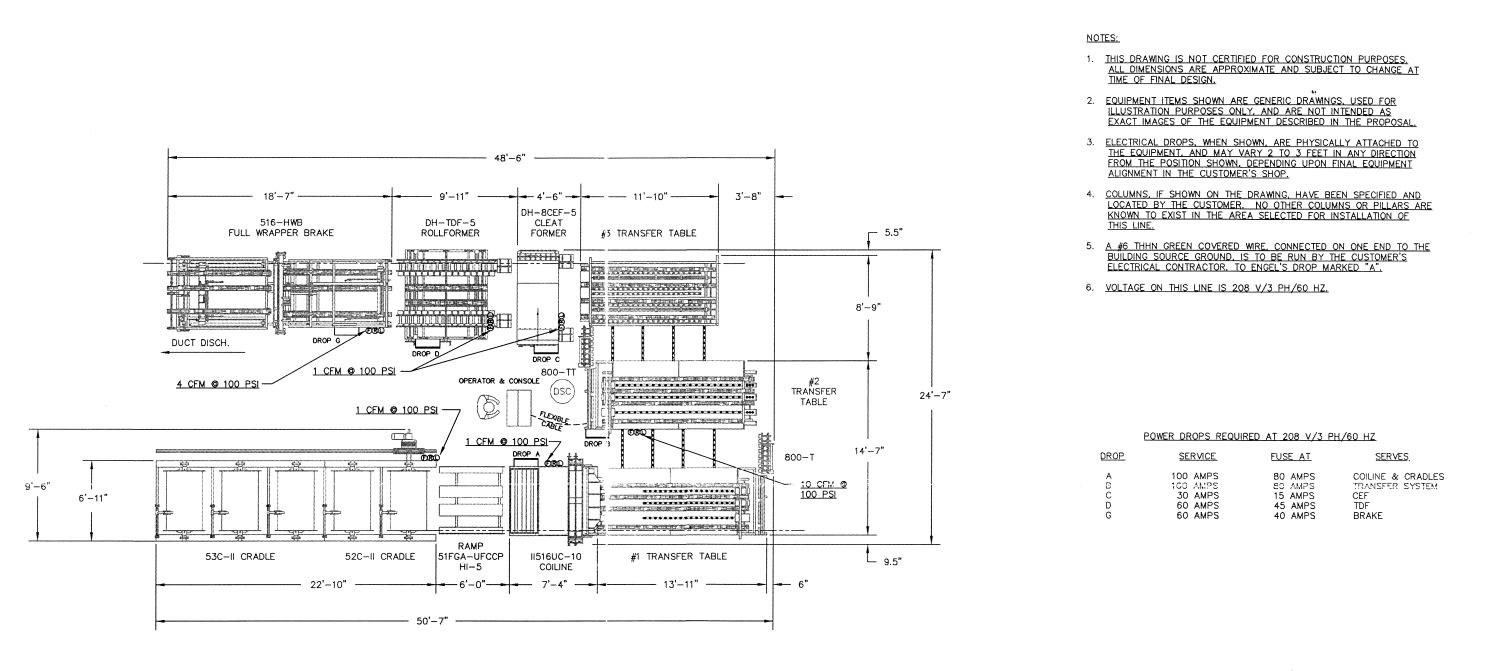

- Material Capacity: Processes up to 16-gauge mild steel

- Decoiler Stations: (5) x 5-foot wide decoilers, each rated for 12,000 lb capacity

- Control System:

- New Iowa Controls console (2019)

- New motor, gearbox, and decoiler control box (2025)

- Power Requirements: Operates on 230V 3-phase power

- Additional Components:

- Leveling rolls and bead rolls

- Large Pittsburgh or Snaplock capabilities

- S&D or TDF connection options

- Full wrap brake included

Productivity & ROI Benefits:

Save on Materials:

Buy coil stock instead of precut sheets—save 30–35% per 10,000–12,000 lbs of steel.

Comparable to buying toilet paper in rolls instead of individual sheets—efficient and economical.

Reduce Labor Costs:

Significantly decreases manual handling by integrating multiple steps into one system. A single ductwork mechanic can cost over $80,000–$100,000 per year—this system reduces dependence on skilled labor.

Streamline Fabrication:

Cuts down on the need for multiple standalone machines and repetitive handling, freeing up floor space and increasing throughput.

Ideal for HVAC sheet metal contractors and fabricators across the United States and Canada who are ready to scale their operations, reduce job site prep time, and increase profitability.

Advantages

- High-quality, ready-to-use setup with modern controls

- Major cost savings in both labor and material

- Rare opportunity to acquire a fully upgraded line without long lead times

- Replacement cost exceeds $800,000 with 1-year manufacturer lead times

- Versatile and expansion-ready with integrated modern controls

Contact us today to request additional details or schedule a viewing.

Website of Interest

SMACNA sets the standards for sheet metal systems and HVAC fabrication, which coil lines are heavily used for.

Reviews

There are no reviews yet.